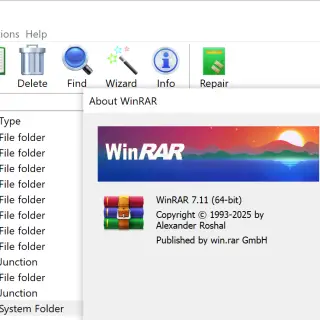

WinRAR Flaw: Bypassing Windows MotW, Code Execution Risk

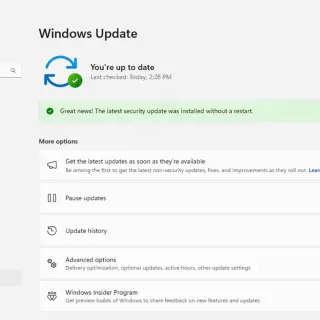

A vulnerability has been discovered in the WinRAR archiving utility that allows the circumvention of Windows’ “Mark of the Web” (MotW) security mechanism, potentially leading to the execution of malicious code. The issue was...