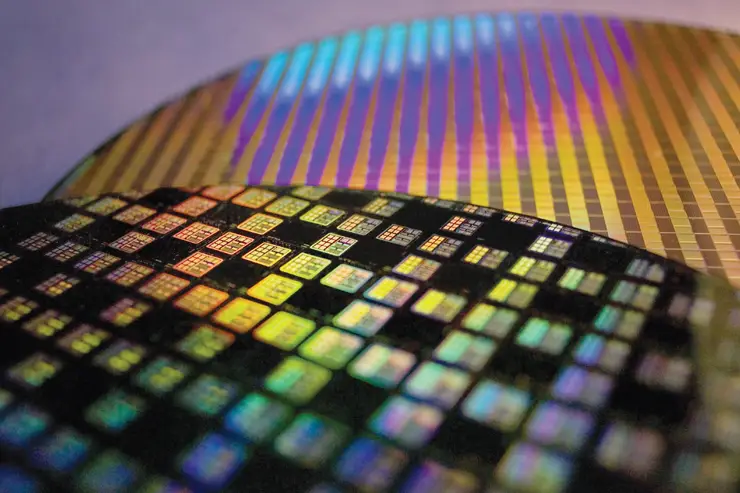

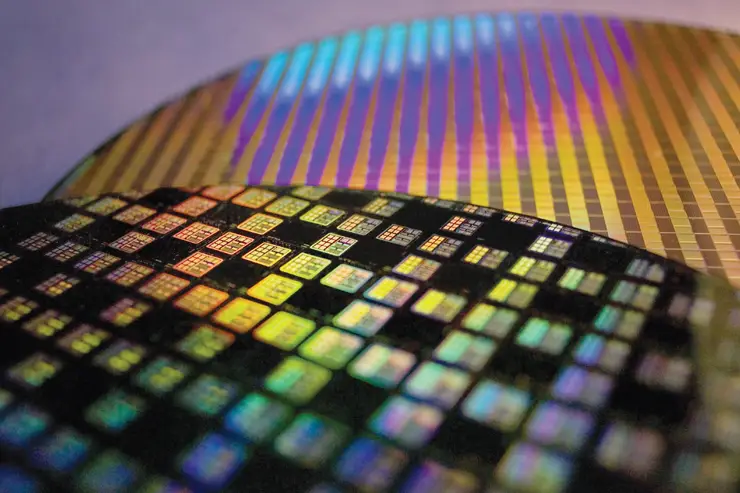

With the rapid advancement of artificial intelligence (AI) technology, the demand for chips has surged dramatically, driving continuous improvements in advanced packaging and high-bandwidth memory (HBM) technology, thereby further increasing wafer consumption. This trend is expected to benefit the silicon wafer industry.

According to Trendforce, Doris Hsu, Chairman and CEO of GlobalWafers, stated that HBM memory chips required for AI processors, such as HBM3 or the upcoming HBM4, necessitate stacking on the chip, increasing the number of layers from 12 to 16, with an additional base chip layer underneath. This is anticipated to significantly elevate wafer consumption.

The AI boom has caused a global shortage of HBM, with memory manufacturers’ capacity for this year and next already sold out, requiring continual capital investment to expand HBM production. Industry insiders have revealed that, compared to storage chips of the same capacity and process like DDR5, HBM chips have a 35% to 45% increase in wafer size. Additionally, the manufacturing process for HBM chips is more complex, with yield rates 20% to 30% lower than DDR5, meaning fewer qualified chips are produced per wafer area. These factors combined necessitate more silicon wafers to meet HBM production needs.

Furthermore, advanced packaging now demands more polished wafers than before, as packaging has become three-dimensional, with changes in structure and process, sometimes requiring double the wafers previously needed. With the release of advanced packaging capacity next year, the number of required wafers will see a more pronounced increase. Currently, TSMC‘s CoWoS packaging is gaining popularity and has been in a state of undersupply for a considerable time.

In the past, the development and application of advanced semiconductor technology reduced chip sizes, lowering wafer consumption. Now, driven by AI and 3D packaging, wafer usage has increased, promoting the growth of the silicon wafer industry. It is worth noting that, alongside the development of silicon wafers, HBM and advanced packaging technologies impose higher demands on quality, flatness, and purity. This will prompt silicon wafer manufacturers to make corresponding adjustments to keep pace with industry trends.